How to Make My Wood Table Tops

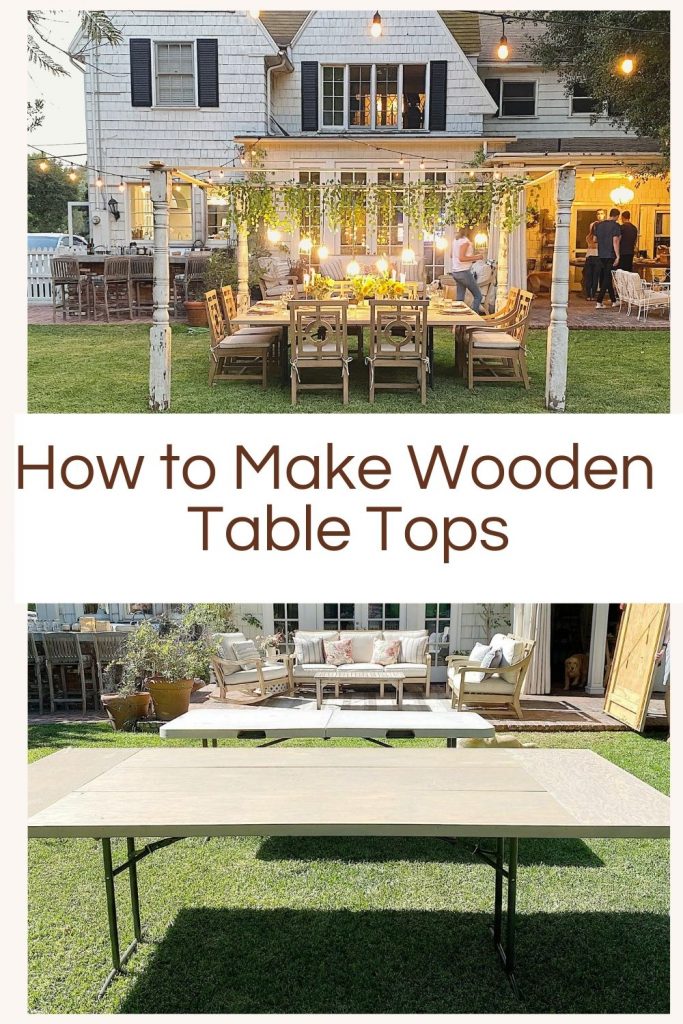

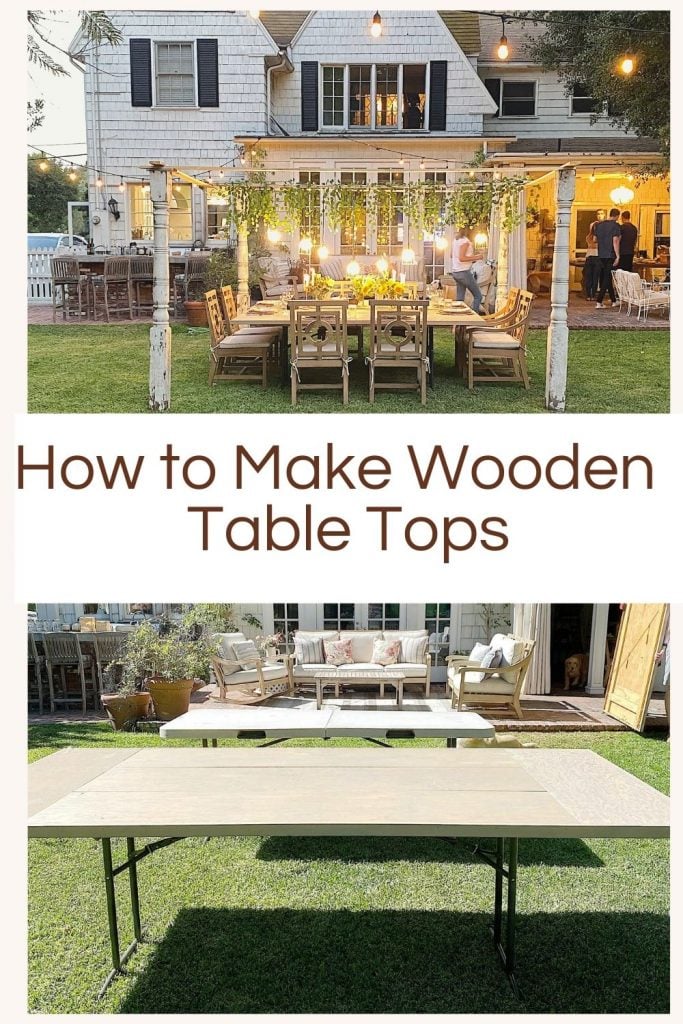

We entertain a lot and I tired of renting plastic tables. So I built my own wood table tops that look like our expensive dining room table! Today I am sharing how to make wood table tops.

You all know how much I love to entertain. Three years ago I came up with an idea to solve my shortage of tables. I designed and made wood table tops that fit over regular plastic folding tables. (The cheap kind.)

The photo above is not an expensive wooden table. It is two homemade table tops sitting on top of two cheap folding plastic tables. Look closely at the table(s) below.

I think this just might be one of my best ideas ever.

Hundreds of you have asked about this DIY. I am so happy to share it today.

If you are enjoying my blog, you can sign up to receive my blog updates here.

.How to Use the Wood Table Tops

In the two years since I made these wood table tops, we have used them dozens of times. You can also see them here, here, and here.

Why Do These Wood Table Tops Work so Well?

Honestly, these work well for a lot of reasons.

- They look nice enough to use without a tablecloth.

- These table tops fit snugly over the plastic tables (there’s a frame underneath) and are very secure.

- They sit 6 – 8 people each.

- If you make two tabletops, they can fit together to make a square or a long table and sit 12 – 14 people.

- Storage is easy. We store our two table tops behind the armoire on our covered back porch. (Although if you look closely at any of our back porch photos you can barely see them behind the armoire.)

You can barely see Andrew and Dave carrying the wood table top outside from the back porch in this photo.

I did have help making these table tops. My handyman (who is used to my crazy ideas and helped build our outdoor planters) has the tools and carpentry knowledge. Between the two of us, we make the perfect team. (Case in point … I had no idea what a biscuit joiner was. I mean, it kind of sounds like a cooking tool. But apparently, it’s not.)

We bought the lumber at Home Depot and brought it home.

When I dreamed up the idea to make these, I thought I was making table tops that would always be covered with a table cloth. Thus, I chose to use cheap lumber. But once I stained them I realized they looked really nice and didn’t need a tablecloth.

I have used our table tops in the dining room many times and friends always ask when I got a “new dining room table”. They have a very farmhouse look and look great with our dining and outdoor chairs.

If I ever make them again I will likely upgrade the lumber. But it certainly isn’t necessary.

What You Need to Make Wooden Table Tops

Three – 1 in. x 6 in. x 8 ft. Premium Kiln-Dried Square Edge Whitewood Common Board

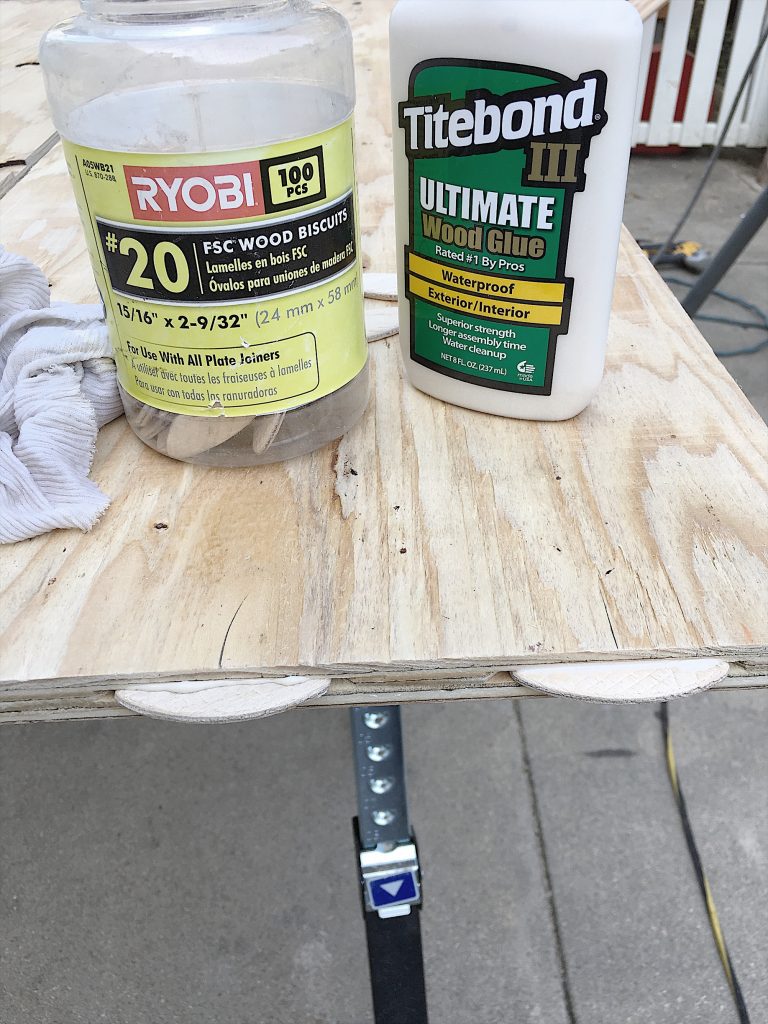

One – #20 FSC Wood Biscuits (and a biscuit joiner tool)

Three – 1 in. x 2 in. x 8 ft. Select Kiln-Dried Square Edge Whitewood Board

One can – Fast Dry Wood Stain (I used gray.)

One six foot plastic folded table.

The finished size of the table is 94′ x 44″. This includes a 1″ trim around the outer edge around the entire table.

Cut Lengths

Cut the plywood into three 14″ x 64″ lengths and two 14″ x 42″ lengths.

Next, cut the 1″ x 6″ boards (for the underside frame) in two 92″ lengths and two 30 1/2″ lengths. (These measurements are based on using a 72″ x 30″ plastic folding table. I suggest you cut the two 92″ boards but wait to cut the shorter boards until later.)

Cut the 1″ x 2″ boards based on your finished tabletop size. Once the table is assembled, remeasure the outside frame and incorporate the mitered edges. The finished table top should measure roughly 94″ x 44″.

The overall design of the tabletop is three vertical long pieces of wood and an additional vertical piece at each end. I copied this from our Pottery Barn table. I think many dining room tables have this same design.

Obviously, we used the nicer side of the wood for the top.

This is the underneath side.

My favorite part of these tables is the underneath side. I wanted the table top to fit snugly on the tables so I put a frame on the underside that would sit perfectly on top of a cheap foldable plastic table.

That might be my most brilliant idea ever.

You can see one of the plastic tables through the gate. Yes, it is one of those cheap tables that many of us already own.

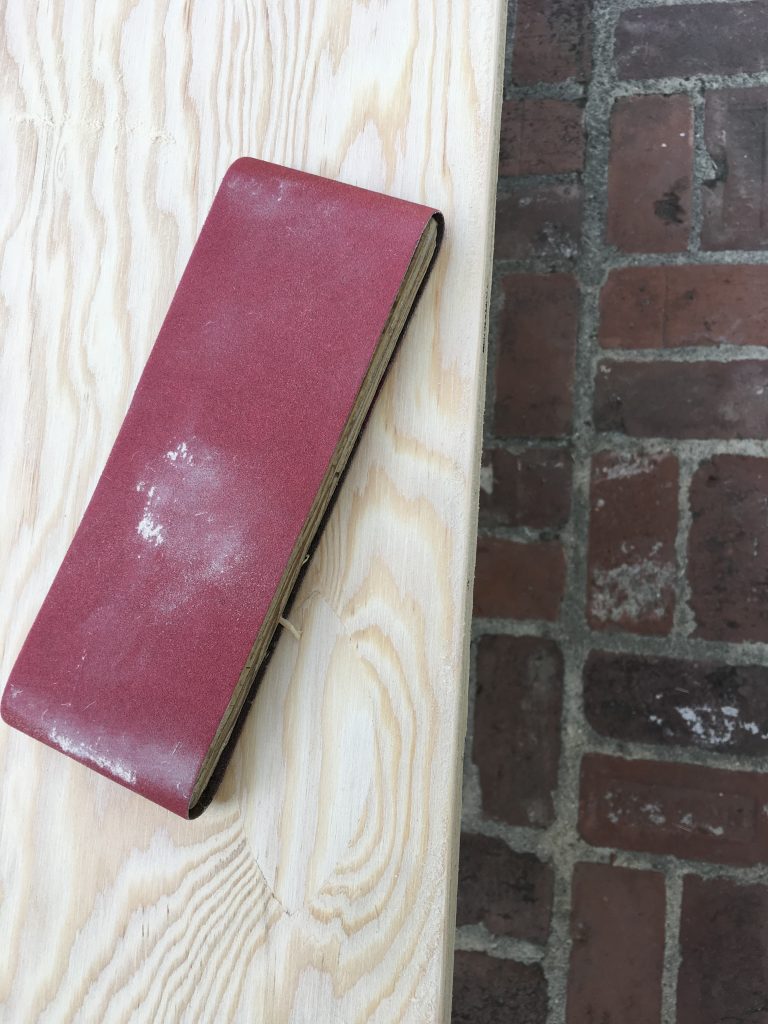

Because of the low-grade wood, there was a lot of sanding involved. With nicer wood, this might not be as necessary. (Note to self for next time.)

Building the Wood Table Top

Even though there is a frame on the underneath side of the table top, you still need to secure the three vertical pieces of wood to the horizontal ends. That’s because the frame doesn’t lay directly below the seam.

To attach the three horizontal boards to each end board, we used a biscuit joiner (which is not a cooking tool). (Please see below as there is a different way to do this without the biscuit joiner.)

You do need a biscuit joiner (or sometimes plate joiner) and it is a woodworking tool used to join two pieces of wood together. It actually cuts a special hole (or slot) at the end of the wood. And yes, I did use this tool! First, I cut two biscuit slots at each end of the longer (vertical) boards. (Don’t try to cut the corresponding slots in the side of the shorter horizontal boards till later.)

Then I gently tapped one of the wood biscuits into each slot.

I didn’t want the boards to be too close together so we added a quarter width between them. (This is certainly not required and caused quite a bit of angst for my handyman. You would think that by now he is used to my crazy requests.)

Next, cut the slots in the smaller horizontal boards.

So how do you get the slots to match? Lay the boards flat and mark a centerline on both sides of the biscuit and cut the slots on the smaller boards accordingly.

Once the slots are cut, place some wood glue into the empty slot and tap the boards together. Let dry.

In case you aren’t too excited about using a biscuit joiner, you could use metal straps to joint the boards instead. The only thing you need to figure out is whether the straps will cause the table to not fit snugly on top of the plastic table. I think if you placed them evenly throughout the underneath side then this might work. It certainly is easier!

The next step is to attach the frame underneath.

Lay the tabletop right side down and mark the center lines with a chalk line. Then place your plastic table on top. Confirm the size of the frame by adding 1/4″ around the outside of the table. Make sure the frame size is in the center of your table and straight on all sides.

Attach the 1″ x 6″ boards to the underneath side of the table top with screws.

Nest, we added a mitered frame around the outside edge.

I wanted the frame to drop down a bit so that it made the tabletop look even thicker than it was. So we used the 2″ side for the drop.

The last step is to stain the tables. I used gray stain but you can use any stain you want. I also didn’t seal the wood but I suggest you use some sort of protective coating as well.

When you are done, your table tops should look like this!

Besides the lumber, here is everything else you need to make these wood tabletops.

Similar Posts

Pin the image below to your DIY or wood project boards on Pinterest (just click the Pin button in the top left corner). You can also follow along with me on Pinterest!

For more real-time updates, follow me on Instagram @My100YearOldHome

Just out of curiosity, why did you NOT want the boards to sit flush against one another on the tabletop? Also, what size tablecloth do you typically use with these if you happen to use one? I’m just interested in what size drop you prefer for entertaining. Thanks…

Thank you so much for posting this. I have been looking forward to it ever since I first saw them! I just love your ideas and your cheeeful attitude!!

Of course, Lorisa. I am so glad you enjoyed!

Such a beautiful and amazing idea, Leslie! I guess you’d have to have a good place to store these tabletops when they’re not in use. Available space is my biggest issue!

You could slide under your bed probably too 🙂

Very true, Lana!

Penny, of course that can always be a predicament. You just have to get creative as to some places that house them.

This is a great idea. Those plastic tables aren’t quite wide enough for regular dining but this top certainly will add enough room for pleasant dining! Thanks for this post!!

Of course, Kay! I am glad you enjoyed.

Love this. Creative solution and beautiful. Honestly. In my next life I want to be a woodworker/furniture maker. I just love the smells, the process and all the possibilities.

Carol, isn’t it so great. That sounds like the greatest job.

Totally brilliant! Can’t wait to show my hubby. Ha!

I tried describing this idea to him two years ago when we were hosting a herd and he talked me out of it, saying it would be too heavy for the folding tables. He needs pictures. I’m onto him. He’s not talking me out of it next time!

Diane! That is too funny, I hope this helps 🙂

My husband is a retired cabinet maker and it looks like I’m going to have a little project for him! Thanks for sharing, they really look fabulous.

The perfect project for him! Thank you so much, Gail.

Brilliant! I cant wait to have my “handyman” make them also😊. They’re absolutely perfect 👌!

Haha! So great, Brenda.

Considering one of my daughters just got engaged and we just bought a new home where they want to have an outdoor wedding next year these tables will be perfect!

Jeanne, that is so sweet and would be just perfect!

Fabulous! I can’t wait to make these. Thanksgiving is dicey on those wobbly plastic tables so these will be a vast improvement! Thanks for posting and for being such an inspiration!

Thank you so much, Kristin! I am so pleased you found inspiration in this 🙂

Ingenious! And absolutely beautiful! You are very generous to share your talent.

Thank you so much, Linda!

Would the weather warp these if you kept them out very long?

I like all your interesting ideas. Thank you so much for sharing decor, recipes and DIY!😘

Of course! I would assume so, but have yet to try that.

What stain did you use?

While the link in the blog post doesn’t work … I read the link and it said Varathane Weathered Gray Premium Stain.

Always wondered about your super huge party table and now I know!

Funny – my hubs made me something similar for a card table – made me a big heavy round piece that sat more – when I was looking at an expensive round table for tea parties.

It had been so nice to use back then. He did a similar form underneath so it would never slide off or jiggle any hot teapots or filled teacups. The heft of it actually made the whole table heavier overall and much nicer.

I haven’t used that thing in years. Didn’t even think of it till I read this. Yes, it was a genius idea. : – )

I would absolutely love to sit at that gorgeous outdoor dining experience. There’s something about that picture that speaks loudly to me – it is magical. I just love it.

Thank you so much for sharing, Michele! That is so great 🙂 So you glad you are here to follow along.

What a clever idea, and they do look very nice stained. I am also wondering, why did you want the quarter spacing between the boards? thanks so much

Leslie,

Maybe I am missing something, if you want 94 x 44 finished top and your plywood is 96 x 48, why not just trim it and add your 1 x 2 trim? It should be more stable, way easier to build and if you ever wanted to re-use the plywood you have a nice solid piece instead of the strips? I don’t get it. Good idea though to frame around the plastic table top, keeps it in place and adds firmness to the top.

I think it gives the table more of a “this is an actual dining table” feel rather than a “just a piece of plywood here, folks” vibe. 😉

Very true, Alicia. Thank you for following along with me!

Amazing! I have been waiting to see this DIY. Questions: do you spray paint the metal under the plastic table? And are these folding chairs you use around them? Thank you!

Thank you, thank you! I love your tables and hope my hubby will help me make some.

Thank you! I hope so too 🙂

Thank you Thank you!

I’ve saved it and sent it to my husband to study!

The paint link didn’t open-what kind of paint?

Wow this is brilliant. Thank you for sharing this idea.